Printing vibrant and accurate colors challenge printing services providers (PSPs) trying to satisfy customers. Understanding the concept of color gamut and its significance in digital printing is crucial to achieving exceptional color quality.

Color gamut refers to the range of colors a specific printing system can reproduce. The combination of inks, substrates, and printing technology affects the reproduction of color. In digital printing, a wider color gamut allows for a broader spectrum of hues and saturation levels, resulting in more lifelike and visually appealing prints.

To understand how to achieve a wider printed color gamut, it is critical to know basic color theory and the factors influencing color perception.

Representation of Color Gamut in Color Spaces

Nothing matches the human eye for viewing a range of colors. The goal is to create a perception that matches the visible color range of the eye as closely as possible.

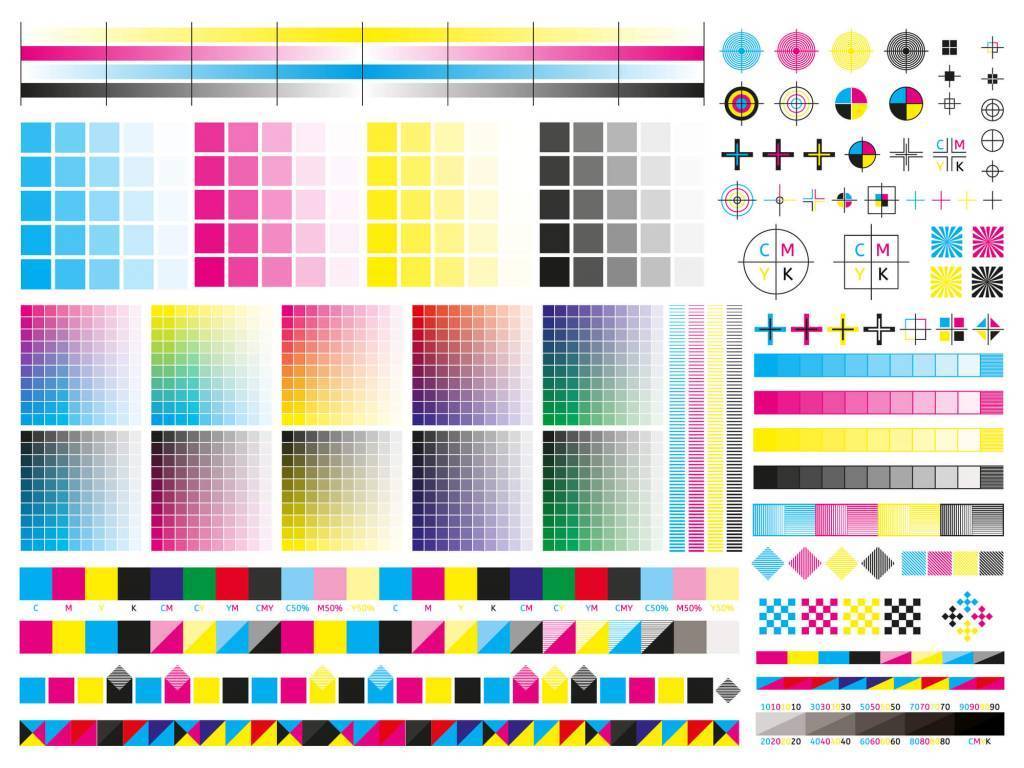

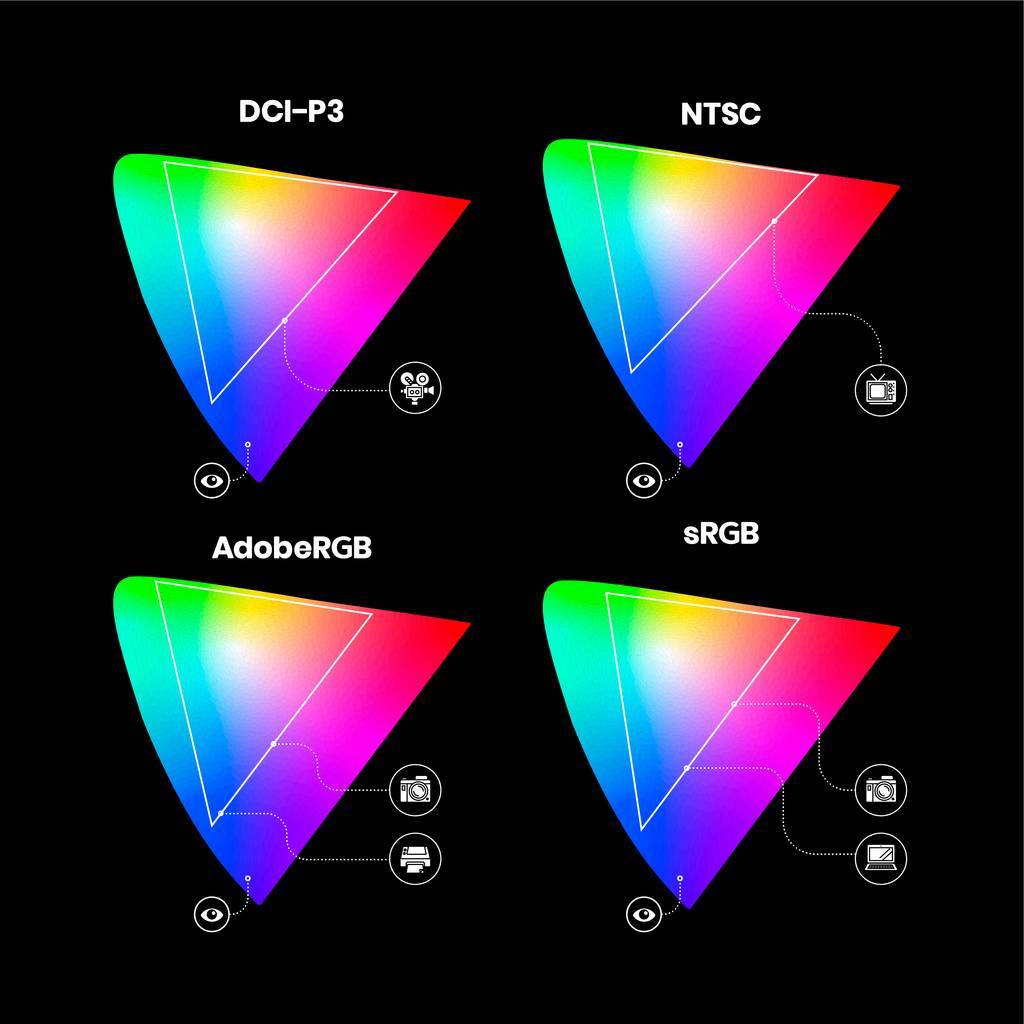

It is represented within standardized color spaces, such as RGB (Red, Green, Blue) and CMYK (Cyan, Magenta, Yellow, Black), which provide a framework for defining and communicating colors in digital imaging.

The RGB color space, commonly used for electronic displays, uses additive color mixing. By varying the intensity of red, green, and blue light, a wide range of colors can be produced. RGB color gamuts are often larger and display more vibrant and saturated colors than other color spaces.

In contrast, the CMYK color space is primarily used in printing. It involves subtractive color mixing, creating colors by subtracting varying amounts of cyan, magenta, yellow, and black inks. The limitations of CMYK ink pigments and subtractive color mixing produce a narrower range of colors than the RGB color space.

Comparison of Color Gamuts in Different Devices

Devices such as monitors, printers, and cameras have unique color gamuts. The ability of a device to reproduce colors depends on factors such as the underlying technology, color calibration, and component quality.

Monitors have inherent color gamuts determined by the display technology and panel quality. High-quality monitors with advanced technologies, such as OLED or wide-gamut displays, display a wider color range.

Printing equipment, including industrial inkjet systems, have color gamuts defined by the inks, printheads, and color management techniques. To ensure accurate color reproduction, the aim is to closely match the printer’s color gamut to the desired color space, such as RGB or CMYK.

When working with digital images, it is essential to consider the color gamuts of the input device, like a camera, and the output device, such as the display or printer, to ensure consistent color throughout the workflow.

Factors Affecting Color Renditions

Several factors influence the appearance of digitally printed colors. Understanding these factors is crucial for achieving accurate and vibrant color reproduction. This section will explore the impact of light sources and illuminants, color temperature and white balance, display technologies, and color profiles with their associated color management systems.

- Light sources and illuminants: The light source used during image capture or viewing can significantly affect color perception. Different light sources, such as natural daylight, fluorescent bulbs, or incandescent lighting, emit varying spectra of light, which can cause shifts in color appearance. Proper color management accounts for the lighting conditions to ensure consistent color reproduction across different environments.

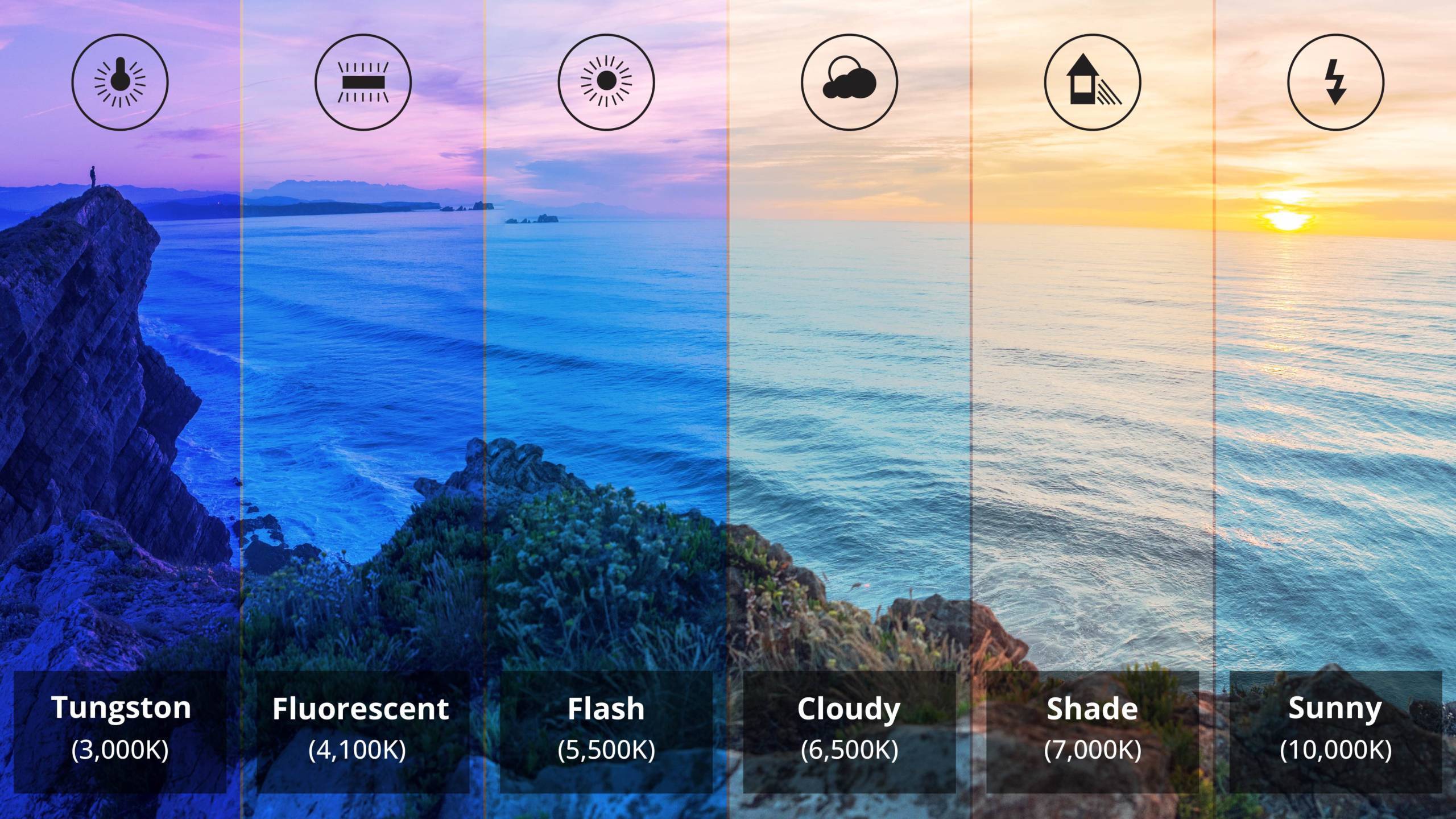

- Color temperature and white balance: Color temperature refers to the warmth or coolness of light. It is measured in Kelvin (K). Different color temperatures can create a bias towards warm yellowish or cool bluish tones in images. White balance adjustments neutralize the color casts caused by the lighting conditions, ensuring accurate color reproduction.

- Display technologies and the impact on color gamut: The choice of display technology, such as LCD, OLED, or LED, can affect the color gamut and accuracy. Advanced display technologies with wider color gamuts, such as wide-gamut monitors, can reproduce a broader range of colors, enabling more accurate color representation during image editing and proofing stages. Examples of wide-gamut displays include high-end professional monitors like the Dell UltraSharp UP3218K or the Apple Pro Display XDR.

- Color profiles and their color management systems: Color profiles are essential in color management. They contain information about input and output devices’ color characteristics and capabilities, such as cameras, monitors, and printers. Color management systems use these profiles to ensure consistent and accurate color reproduction across different devices by converting colors between various color spaces and accounting for each device’s specific color gamut limitations.

Challenges of Achieving Wide Color Gamut

Achieving a wide color gamut in industrial inkjet printing systems comes with various challenges. Printer limitations, ink limitations, spot colors, color matching, and substrate influences can all impact the ability to achieve accurate and vibrant color reproduction.

Printer Limitations

Industrial inkjet printers may have inherent limitations in printhead technology, ink deposition accuracy, and color management capabilities, affecting the ability to reproduce a wide range of colors accurately. Addressing these limitations is crucial for optimizing color gamut expansion.

Ink Limitations

Spot Colors and Color Matching

Specific brand colors are challenging to reproduce accurately using only CMYK inks. These spot colors may require custom ink formulations or other spot color inks to achieve precise color matching.

Standard CMYK ink sets used in printing have inherent limitations in reproducing specific colors due to their subtractive color mixing process. Technically, the combination of cyan, magenta, and yellow should produce black. The reality is something closer to muddy, brown-black.

“Clean pigments” render colors more faithfully. For example a purer magenta would have less black or other impurities. Color profiles help account for ink differences.

Dye-based inks offer vibrant colors but may be susceptible to fading, while pigment-based inks provide better color stability but may have a slightly narrower color gamut.

Substrate Influence

The color of the substrate or printing surface can influence color reproduction. Substrates may interact differently with inks, affecting color vibrancy, saturation, and overall appearance. Understanding and accounting for substrate characteristics are essential for consistent and accurate color reproduction.

How To Achieve Wider Color Gamut

Achieving a wider color gamut in industrial inkjet printing requires precise calibration and implementation of effective color management systems. This section explores the importance of calibration at every step, including device calibration and profiling.

Achieving a wider color gamut in industrial inkjet printing requires precise calibration and implementation of effective color management systems. This section explores the importance of calibration at every step, including device calibration and profiling.

We will also discuss color management systems, hybrid ink systems, and various color gamut extension methods such as gray component replacement, under color removal, and the benefits and limitations of different ink types and extended ink sets.

Calibration, Calibration, Calibration – Every Step of the Way

Calibration is crucial to achieving a wider color gamut. It involves accurately adjusting and aligning devices at every step of the printing process, from cameras or scanners to monitors and printers. Calibrating devices, including color settings, white balance, and color profiles, ensure consistent and accurate color reproduction throughout the workflow.

Device Calibration and Profiling

Device calibration involves adjusting and optimizing the settings of individual devices, such as monitors and printers, to ensure accurate color reproduction.

Device calibration involves adjusting and optimizing the settings of individual devices, such as monitors and printers, to ensure accurate color reproduction.

Profiling, on the other hand, involves creating color profiles that accurately represent the color characteristics of specific devices. Calibration and profiling enable precise color conversion and consistent color reproduction across different devices.

Color Management Systems and Hybrid Ink Systems

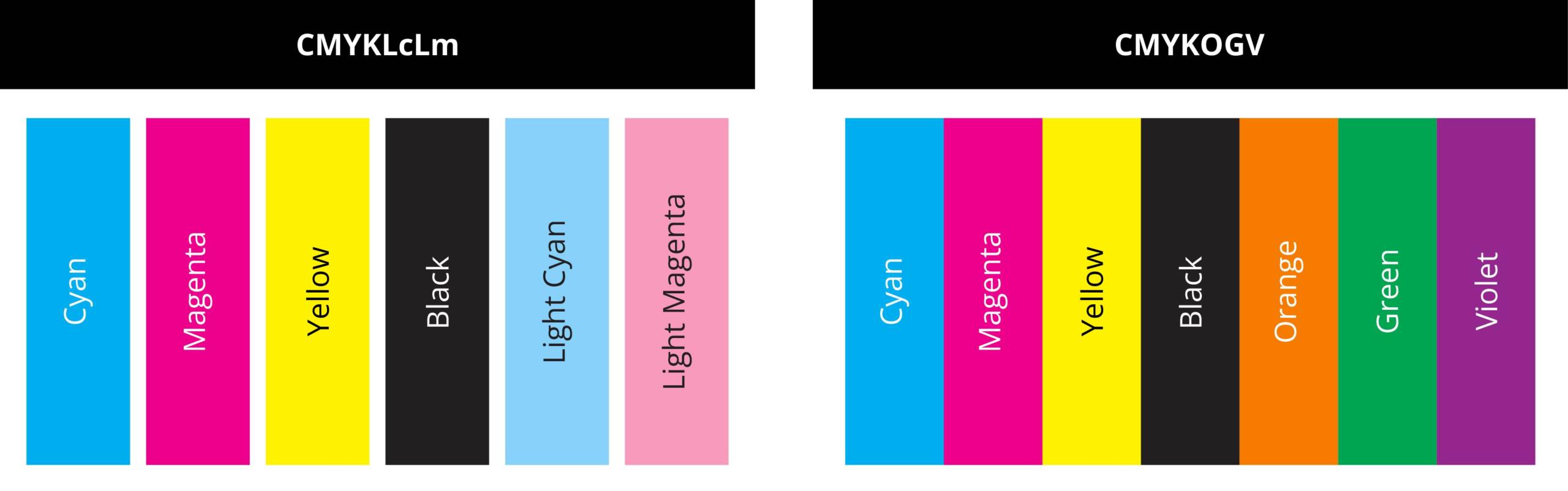

Color management systems play a vital role in achieving a wider color gamut. These systems use color profiles and advanced algorithms to ensure color consistency and accurate color reproduction across various devices. Hybrid ink systems that combine dyes and pigments or extended CMYK ink sets, such as CMYK+White, CMYKLcLm, CMYKOGV expand the color gamut by offering a broader range of colors

Color Gamut Extension Methods

Color gamut extension methods, such as gray component replacement (GCR) and under-color removal (UCR), can help expand the color gamut. Gray component replacement involves using black ink to replace a portion of the cyan, magenta, or yellow inks to achieve more accurate neutral colors.

Color gamut extension methods, such as gray component replacement (GCR) and under-color removal (UCR), can help expand the color gamut. Gray component replacement involves using black ink to replace a portion of the cyan, magenta, or yellow inks to achieve more accurate neutral colors.

Undercolor removal reduces the amount of cyan, magenta, and yellow inks to create brighter and more saturated colors. However, these methods have limitations and must be carefully implemented to avoid color shifts and loss of detail.

Dyes vs. Pigments

Choosing dyes and pigments in ink formulations impacts color gamut and print quality. Dyes offer vibrant colors but may have less durability and color stability over time. Pigments provide better longevity and color stability but may have a slightly narrower color gamut than dyes. Understanding the characteristics and trade-offs of each ink type is essential when aiming to achieve a wider color gamut.

Choosing dyes and pigments in ink formulations impacts color gamut and print quality. Dyes offer vibrant colors but may have less durability and color stability over time. Pigments provide better longevity and color stability but may have a slightly narrower color gamut than dyes. Understanding the characteristics and trade-offs of each ink type is essential when aiming to achieve a wider color gamut.

Effects of Color Gamut

Color Accuracy and Fidelity

A wider color gamut allows for more accurate color reproduction, ensuring that colors are represented faithfully and with greater precision. By expanding the color gamut, industrial inkjet printing systems can achieve better color accuracy and fidelity, resulting in prints that closely match the intended colors.

Vibrance and Saturation of Colors

A wider color gamut reproduces more vibrant and saturated colors. With an extended color gamut, industrial inkjet printing systems can achieve prints with enhanced vibrancy and saturation, resulting in visually striking and vivid color representations.

Subtle Tonal Variations and Gradients

A wider color gamut enhances the ability to reproduce subtle tonal variations and smooth gradients. By expanding the color gamut, industrial inkjet printing systems can accurately render intricate tonal transitions, resulting in prints that exhibit greater depth, realism, and smoothness in gradients.

Reproduction of Specific Color Ranges

A broader color gamut allows for more accurate reproduction of specific color ranges, such as skin tones, blues, or any other colors relevant to the application. With an extended color gamut, industrial inkjet printing systems can better capture and reproduce the nuances and complexities of these specific color ranges, ensuring that they are faithfully represented in the final prints.

Quality Inks: The Backbone of a Reliable Color Control Workflow

Producing colors closest to matching what the eye perceives requires controlling variables. Achieving an extended color gamut requires careful calibration, device profiling, and the implementation of effective color management systems. And choosing the right inks

A reliable supplier of quality inks supports the color control workflow. Independent industrial inkjet manufacturers, like Kao Collins, follow strict quality controls and collaborate with major printhead manufacturers to develop compatible ink formulations.

By harnessing the potential of an extended color gamut, businesses can elevate the quality and impact of their prints, delivering visually stunning results that meet the demands of today’s color-centric market.

Contact Kao Collins about our standard and extended CMYK inks and custom color-matching services.

FAQs

Color gamut refers to the entire range of colors that a specific printing system or device can reproduce.

Beyond CMYK refers to printing technologies and ink sets that go beyond the traditional cyan, magenta, yellow, and black (CMYK) inks, enabling the use of additional colors or special effects in the printing process.

CMYKOGV is an extended ink set that includes cyan, magenta, yellow, black, orange, green, and violet inks. It expands the color gamut and allows for a wider range of colors to be reproduced.

CMYKLCLM is another extended ink set that includes cyan, magenta, yellow, black, light cyan, and light magenta inks. It provides finer control over color reproduction, particularly in areas that require subtle tonal variations and smoother gradients.

Using white ink alongside CMYK inks allows for better opacity and coverage on dark or transparent substrates, ensuring that colors appear vibrant and accurate. White ink can also be used as a base layer to enhance the brightness and vibrancy of other colors in the printing process.