Thanks to a new advances in inkjet research, the ever-evolving printing technology may be used to print directly onto aircraft fuselages, tails, and wings.

6 innovative bus wrap designs

Traditionally, companies applied decorative finishes to airplanes through one of two methods: vinyl decals and stenciled painting. Painting on aircraft with stencils dates back to the earliest days of air travel. Stencils are applied to the aircraft not only to ensure a specific design is followed, but also to ensure paint is not applied to rivets, bolts, or openings where paint could cause a problem in functionality.

Vinyl decals, often printed using wide-format inkjet printing methods, are printed on a separate substrate and then applied to the aircraft. This process usually results in professionally finished, higher resolution finishes to aircrafts, but it does have a few drawbacks. It requires additional steps and labor because the ink is not deposited directly on the surface.

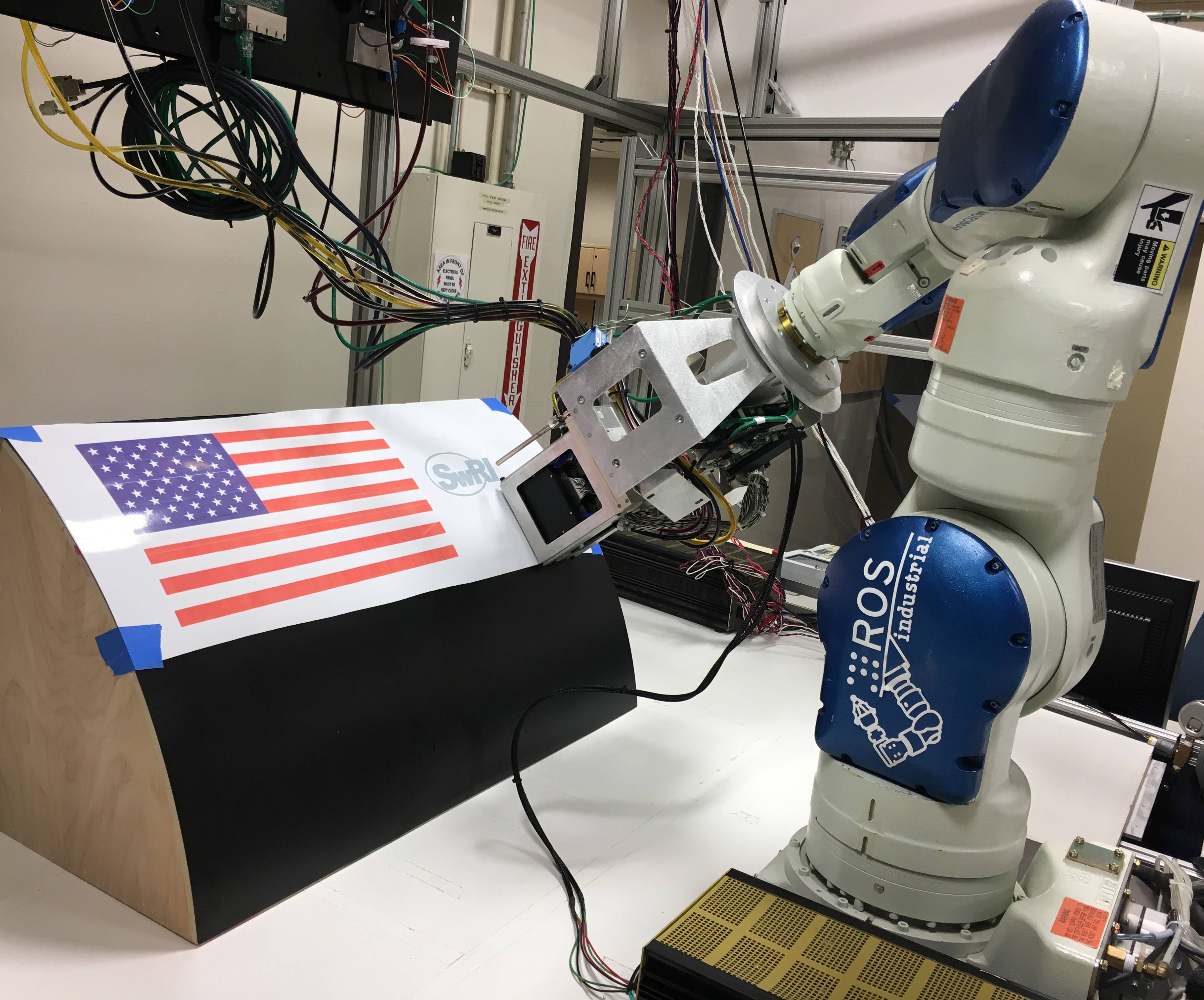

New inkjet research suggests in the future, logos and designs may be mechanically printed directly onto aircraft hulls. The method is a large-scale robotic technique that uses an optical scanner and a large robotic arm alongside a direct-on-demand inking system.

One of the biggest challenges in using inkjet on aircraft is the complex geometry of the surface. In addition to the curvature of the plane itself, windows, doors, and rivets are all obstacles a traditional printing method could not easily print directly on, if at all. This new research’s robotic platform and technology allow for the ink to be printed on three-dimensional surfaces in a single run.

The accuracy inkjet printing allows has very real safety benefits. Airplanes are meticulously engineered to be aerodynamically sound and safe from harsh operating conditions, and they have to remain safe and functional for decades. Finishes like paint, ink, and decals can affect the aerodynamics of the plane and so need to be applied with calculated accuracy.

Explore the inks available for PIJ, TIJ, CIJ printing systems

The finishes also play a large role in preventing corrosion. Inkjet technology’s high accuracy helps ensure aircraft continues to meet rigorous safety standards.

Outside of aircraft, the technology has a wide number of applications for a variety of large vehicles with curved, beveled, riveted, or otherwise complex surface areas.

As the industry continues to innovate, it’s clear that inkjet has grown to be a technology that a variety of industries can look to for efficiencies and advantages.

Contact Kao Collins to discuss custom inkjet ink formulations.

READ MORE

20 Unique Product Packaging Ideas

8 Creative Billboards That Make You Slam on the Brakes

Food-grade ink regulation focuses on ‘Do no harm’

Creative Digital Inkjet Driving Digital Wallpaper Renaissance