Key Takeaways

→ Low-cost inks often result in costly downtime, poor print quality, and safety risks.

→ Budget inks may save money initially but lead to higher long-term expenses.

→ Investing in quality inks ensures consistent performance and protects your brand.

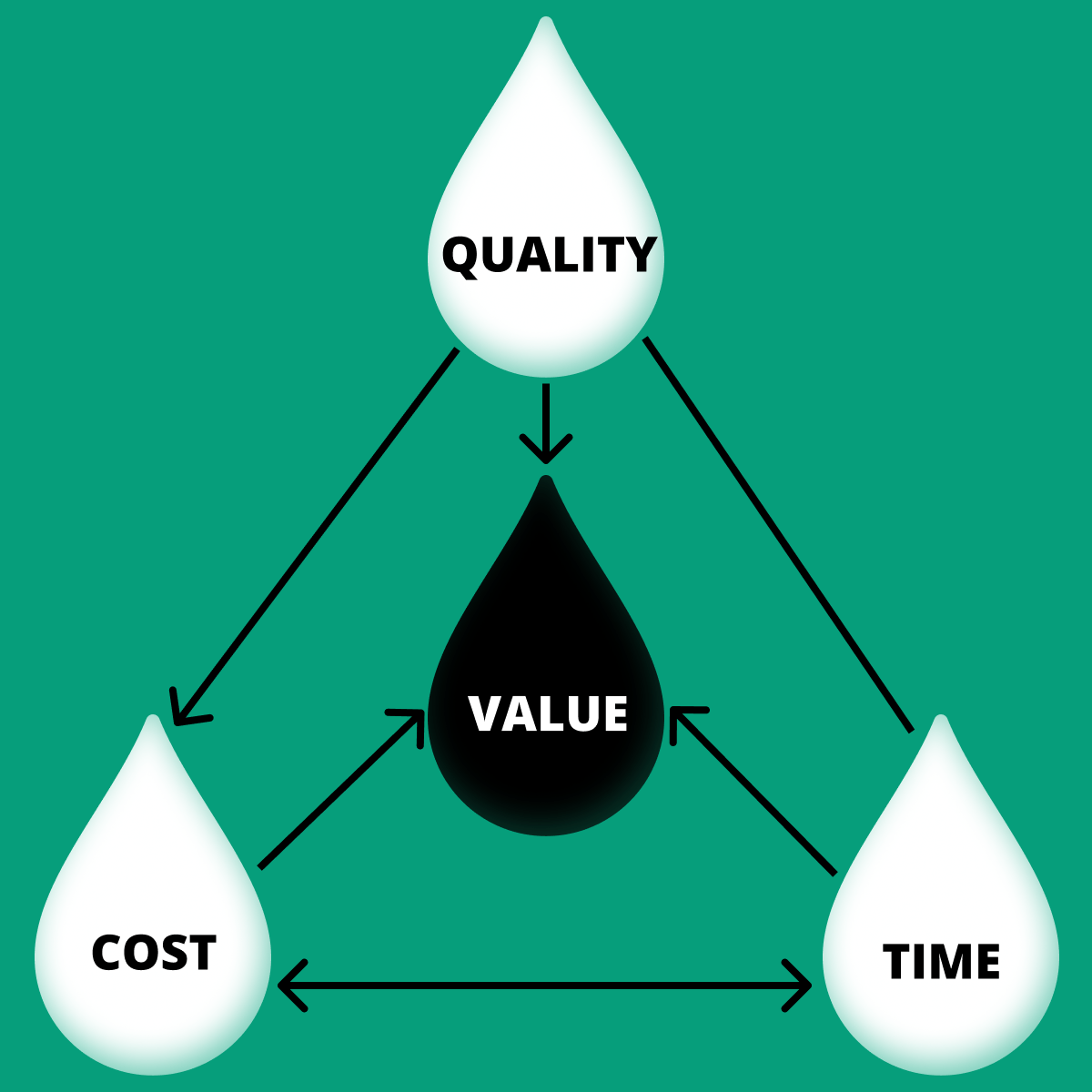

The never-ending struggle between cutting ink costs and achieving quality creates tension between financial and quality managers, with production managers stuck in the middle.

Cheap industrial inks attract buyers like a moth to a lamp, each unaware of the risks.

Downtime, printhead malfunction, and low print quality chip away at margins.

For example, unplanned downtime costs are skyrocketing. In every sector surveyed in a 2022 Siemens report, an hour of unexpected downtime now costs manufacturers at least 50% more than it did two years ago.

A dissatisfied customer is the biggest risk to the bottom line.

What may be a small win in the ledger and quarterly results can turn into mounting losses. The actual cost of cutting corners is on the balance sheet. It’s in product failure and the erosion of trust.

Adverse Effects of Using Low-Cost Ink

Budget industrial inkjet inks often compromise essential specifications, achieving short-term results at greater cost over the long run.

Here’s a look at the tradeoffs when purchasing low-cost inks for industrial and commercial applications.

Cost sacrifices quality, and often time if work must be redone.

Low-cost inks often equate with low quality. These are some of the issues.

- Adhesion

- Durability

- Color inconsistencies

- Opacity and optical density

- Migration

- Smearing

- Printhead failure

- Downtime

- Line speed

- Set-off

- Peeling and cracking

Decreased Print Quality

Low-cost inks come at the expense of quality.

Numerous technical specifications comprise ink formulations that produce high-quality results. Low-cost inks mean low-quality chemistry and that means low-quality results.

There’s no getting around it.

Poor quality manifests in issues like streaking, smearing, blotching, poor adhesion, durability, optical density, and more. Greater risks include the impact on the environment or the health and safety of employees or end users.

“Low-cost inks attract buyers with their price but often result in more issues and higher long-term costs,” said Firstname Lastname, title.

Here’s a look at the chemistry in low-quality inks that may affect print results performance expectations.

Fast Drying

Low-cost inks may not offer optimal drying time.

In the inkjet printing industry, the drying time of ink is crucial for maintaining production efficiency.

Slower-drying inks increase the risk of set-off migration and smudging. Production managers compensate for slower drying inks with lower line speed or incorporating heaters or blowers.

A slower line speed means less throughput. Heaters or blowers increase equipment and energy expenses.

High-quality inks optimize drying using high-quality materials in precise formulations that balance humectant types, concentrations, and substrate compatibility to ensure consistent print quality and speed.

Inks to Consider

Solvent-Based: SIGMA+ | SIGMA2 | Solv-Jet

Water-Based: Pitch Black | EcoFast | Reliable H | Endurance

High Optical Density

Low-cost inks have inferior dyes and pigments that jeopardize barcode printing.

Cheaper inks lead to decreased optical density because they often contain less pigment and lower-quality pigments.

These low-cost inks may have irregular droplet sizes that affect ink opacity when combined with the print head. As a result, they produce prints that lack rich, deep blacks or dull colors.

Additionally, the inconsistency of low-quality inks across different substrates can cause issues like streaking, blotching, and poor contrast.

Low optical density leads to faded or blurry prints and barcode scannability issues in the marking and coding sectors of food, beverage, pharmaceutical packaging, and automotive parts labeling.

This risks rejected products, resulting in chargebacks and reduced credibility.

Inks to Consider

Solvent-Based: SIGMA+ | Solv-Jet

Water-Based: Pitch Black | Endurance | EcoMax

Adhesion and Wetting

Low-cost inks run the risk of rub-off or smearing.

Low-cost industrial inkjet inks often struggle with adhesion and wetting due to inferior formulation and chemical properties, including inadequate control of viscosity and surface tension.

These inks fail to establish a strong bond with substrates because improper viscosity disrupts the ink’s spreading, while poor surface tension control impairs proper wetting.

These factors worsen adhesion, leading to inconsistent coverage and an increased risk of print defects.

At the end of the day, prints may suffer from smudging, fading, or peeling.

Inks to Consider

Solvent-Based: SIGMA+

Water-Based: EcoMax

Curable: UV Ultra | LED Tesla

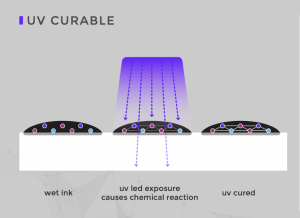

High-Quality Photoinitiators (Piezo UV, LED)

Low-cost, low-quality curable may not set thoroughly.

Low-cost UV and LED curable inks often rely on low-quality photoinitiators to shave costs.

The unintended result is a significant risk of ink migration issues that pose potential health and safety risks in addition to lower print quality.

Chemical migration, where harmful ink components move through packaging materials, can lead to health risks in food and pharmaceutical products.

Incomplete curing also causes set-off migration, resulting in transfer marks and compromised print clarity.

Inks to Consider

These inks use high-quality photoinitiators for safe, rapid curing.

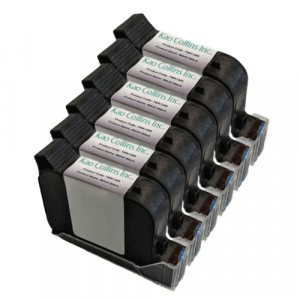

Refurbished vs. New Cartridges

Kao Collins uses genuine OEM factory-new cartridges

As already noted, low-cost inks are often associated with subpar performance, leading to issues like poor adhesion, fading, and inconsistent color output.

Similarly, cost-cutting with non-OEM cartridges introduces new risks.

When looking to cut costs, it’s tempting to opt for ink suppliers shaving prices by packaging industrial inkjet inks refurbished or third-party industrial inkjet cartridges. That’s understandable.

Compared to factory-new OEM cartridges, refurbished and third-party cartridges can cause inconsistent ink flow, leading to substandard print quality. Also, these cartridges tend to fail more frequently, resulting in costly printhead or nozzle failure. The unexpected downtime for wiping and purging erodes the enticing initial savings.

Shelf Life

Higher-quality inks offer reliable shelf life.

The industrial inkjet ink shelf life is crucial for inventory management and cost savings from volume purchasing.

Low-quality inks often deteriorate faster, resulting in waste and higher costs that include replacement products and environmental disposal.

Rolling the dice on expired ink can lead to nozzle clogs and costly printhead failures that require maintenance downtime.

Furthermore, defects and inconsistent colors can compromise the print quality, leading to customer dissatisfaction and potential reprints.

Inks to Consider

Solvent-Based: SIGMA+ | Solv-Jet

Water-Based: Pitch Black | Endurance | EcoMax

Safety and Compliance

![]() Safety and compliance are crucial in industrial settings.

Safety and compliance are crucial in industrial settings.

Using low-quality industrial ink that doesn’t meet safety standards, such as non-CMR and PFAS-free formulations, can lead to serious health risks and potential legal liabilities, impacting consumer, worker, and environmental safety.

Inks to Consider

Solvent-Based: SIGMA+ | SIGMA2 | SIGMA

Water-Based: Pitch Black | EcoFast | Reliable H | Endurance

Decap Time

Low-quality industrial ink can lead to increased downtime due to frequent nozzle clogs and maintenance issues. When ink dries in the nozzles, extensive wiping and purging to remove blockages can disrupt production and increase operational costs.

Low-quality industrial ink can lead to increased downtime due to frequent nozzle clogs and maintenance issues. When ink dries in the nozzles, extensive wiping and purging to remove blockages can disrupt production and increase operational costs.

A typical large plant experiences 25 hours of unplanned downtime per month, which amounts to more than a full day’s production, according to the Siemens study.

High-quality ink formulations, chemically engineered for fast drying and longer decap times, help minimize these issues, ensuring smoother transitions between jobs and reducing the need for frequent maintenance.

Inks to Consider

Solvent-Based: SIGMA+ | SIGMA2 | SIGMA

Water-Based: Pitch Black | EcoFast | Endurance | EcoMax

Customer Satisfaction and Brand Reputation

For print service providers and packagers, maintaining consistent print quality is key to business success and reputation. Opting for low-cost industrial inks offers short-term savings, while the long-term costs can be substantial.

Low-cost industrial inks often lead to higher rejection rates and chargebacks, such as issues with barcode scanning, and other issues that risk business contracts and revenue.

Additionally, using inferior inks poses compliance and safety risks, potentially leading to legal issues and compromising product safety. Investing in high-quality inks ensures not only consistent print quality but also adherence to industry standards, protecting your business and supporting long-term success.

Choose Quality for Long-Term Success

Selecting the right ink for industrial inkjet printing is more than a budget line item or quarterly financial results.

“Low-cost inks chip away at profitability with frequent print issues and higher maintenance costs,” Mr. Lastname said.

It’s a decision that affects your entire production process, from print quality to customer satisfaction.

Premium inks prevent issues associated with inexpensive options.

For expert advice and recommendations on top-quality industrial inks, contact Kao Collins today.