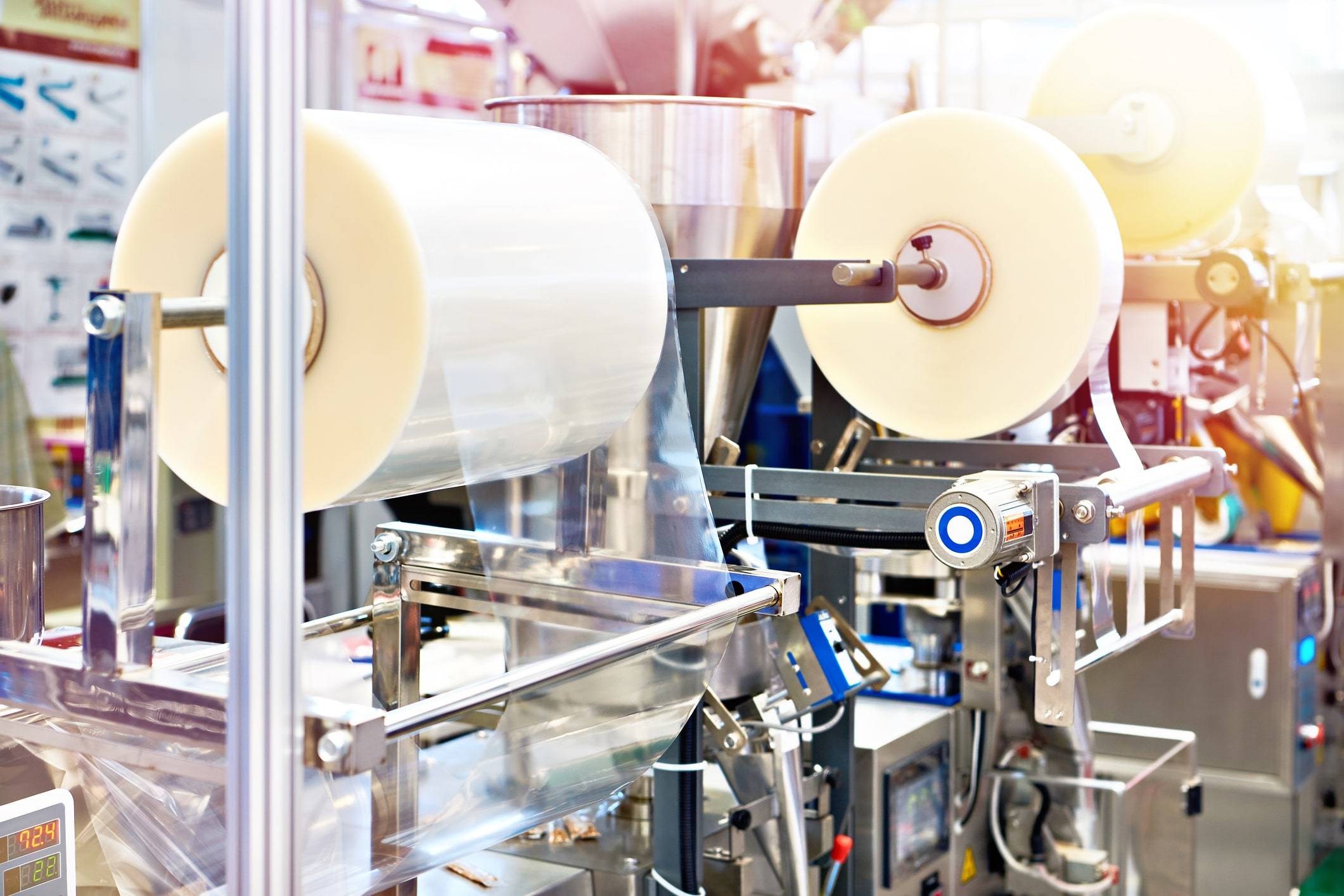

Single-serve meals and beverages in squeeze pouches are convenient for storing and traveling.

We’re always on the move, grabbing meals and snacks on the go. We want convenience at our fingertips and expect it to be perfectly packaged.

This fast-paced lifestyle, combined with varying food preferences, drives the explosive growth of flexible food packaging, especially for single-serve options.

It’s not just food. Projections anticipate the global market for flexible packaging surging from $208.7 billion in 2023 to a projected $360.2 billion by 2030, according to a Research and Markets report.

The industrial inkjet printing sector feels the ripple effects as it adapts to meet increasing market demands.

What’s Driving the Growth

The rise in single-serve flexible food packaging is driven by modern convenience, health-conscious choices, and a need for sustainable solutions. This packaging trend addresses consumer demand for easy-to-use, portion-controlled, and eco-friendly options.

1. Effortless Eating

Convenience is king in today’s fast-paced world. Consumers crave options that fit into busy lifestyles, and single-serve packaging delivers. It makes it easy to eat anytime, anywhere. It also makes meal preparation easier for family members with different tastes, dietary restrictions, and preferences.

Single-serve meals and beverages in squeeze pouches are convenient for storing and traveling.

2. Portion Control

Health-conscious consumers are turning to single-serve packaging for better portion control. With obesity on the rise, pre-measured portions make it easier to manage caloric intake, especially for anyone following specific diets or nutritional plans.

3. Variety and Personalization

Consumers want choices – spicy, salty, low-salt, smokey, etc. – and their demands for variety are growing. Single-serve packaging makes it easier for brands to offer more flavors and dietary options, from vegan to gluten-free. It also allows companies to experiment with new products without lengthy production runs.

4. Population Growth and Urbanization

With more people living in cities and smaller spaces, there is a greater demand for convenient, space-saving food packaging. Single-serve portions reduce waste and fit easily into limited storage spaces, meeting the needs of urban dwellers, single-person households, and busy professionals.

5. Sustainability

Consumer demand and regulatory pressure are two sides of the sustainability coin. Environmentally conscious consumers are demanding packaging that reduces waste and their carbon footprint, while regulators are mandating packaging that reduces environmental impact.

Inkjet Helps Brands Solve Flexible Packaging Challenges

Inkjet inks must balance material compatibility, regulatory compliance, sustainability, and advanced functionality to meet the needs of global brands and emerging markets.

With the growing market for convenient food solutions, industrial inkjet technology has a prime opportunity to capitalize on this growth trend. However, the industrial inkjet printing industry faces challenges as it adapts to the demands of flexible on-the-go food packaging.

Ink manufacturers must address key issues to effectively support emerging markets and established global brands:

- Material Compatibility: Flexible packaging materials vary widely, and inks must adhere well to different substrates while maintaining print quality. Industrial inkjet printing is already well-positioned to address this challenge with formulations designed to handle a diverse range of substrates effectively.

- Regulatory Compliance: As emerging health, safety, and environmental risks are identified, inkjet inks must adapt to the latest scientific findings and regulatory standards for non-toxicity and safety in indirect food contact. Navigating stringent requirements poses substantial challenges.

- Sustainability: The move to more sustainable packaging solutions requires eco-friendly inks. Creating biodegradable or recyclable inks requires maintaining performance.

- Durability and Functionality: Innovative inks now require more than resistance to environmental conditions. To deliver value to manufacturers and end users, new inks may include features like temperature sensitivity and antimicrobial properties.

- Supply Chain Issues: From sourcing raw materials to shipping final products, including ink delivery, the global supply chain faces unprecedented variables, with ongoing threats and risks that can affect ink manufacturing and the food packaging industry.

By addressing these challenges head-on and leveraging technological advancements, the inkjet printing sector can support the current demands of global brands and new market entrants and drive the next wave of growth and innovation in the packaging industry.

Inkjet Ink Options For Printing Flexible Packaging

Plastics are the common choice for flexible food packaging. It’s convenient, light, inexpensive, and keeps food fresh. Options include stand-up pouches, single-serve sachets for condiments, spouted pouches for liquids, plastic wraps for deli items, and thermoformed trays for ready-to-eat meals.

Common plastics such as polyethylene (PE), polypropylene (PP), and polyester are widely used and often feature inkjet printing to include essential information like expiration dates, lot numbers, and barcodes.

Solvent-based inks are cost-effective choice for marking and coding.

Plastic alternatives are gaining traction for packaging on-the-go foods. Aluminum foil, valued for its barrier properties, is ideal for protecting sensitive items from moisture, light, and oxygen. Inkjet printing on aluminum can also provide high-resolution graphics and essential product details.

Paper-based packaging is becoming more popular for dry goods due to its recyclability and biodegradability, though it offers less protection. Inkjet printing on paper can effectively convey branding and product information while aligning with eco-friendly practices.

Lastly, bio-based materials like polylactic acid (PLA), derived from renewable resources, provide compostable options with good barrier properties. Inkjet printing on these materials offers a sustainable way to achieve clear, impactful packaging design.

“No matter the substrate—plastic, paper, or aluminum—our inks bring superior clarity and protection to food packaging, combining functionality with environmental responsibility,” said Bridget Wyatt, Business Development Manager at Kao Collins, highlighting the versatility and performance of printing solutions across various materials.

Solvent Inks Shake Up the Flexible Packaging Scene

Solvent-based inks are a preferred choice for flexible packaging. Fast drying times and strong adhesion to plastic surfaces make them ideal for high-speed production environments where quality and efficiency are crucial.

“We’re all about striking the perfect balance—efficiency, sustainability, and compliance without compromising performance in our solvent-based inks,” Ms. Wyatt said.

Thermal Inkjet (TIJ) technology, like HP and Funai, with enclosed cartridges enhances these benefits with a cleaner, safer, and more efficient printing process.

While Continuous Inkjet (CIJ) technology is also popular for handling high-speed, continuous printing, the equipment involves more complex maintenance and ink waste.

Each technology has its trade-offs, but TIJ’s operational efficiency and environmental control advantages make it a standout option for many flexible packaging applications.

Advantages of Solvent-Based Inks

- Fast Drying: Solvent-based inks dry quickly, enabling rapid turnaround and high-speed printing while also reducing migration risk.

- Strong Adhesion: These inks adhere firmly to plastic, keeping prints clear and intact during handling and transportation, which is crucial for maintaining the quality of product labels and branding.

- Versatility: Solvent-based inks are compatible with multiple plastic substrates, offering flexibility for a range of packaging applications and various product types.

- Cleaner and Safer Operation: Enclosed ink cartridges in TIJ systems minimize spills and contamination.

- Low Maintenance: Enclosed cartridges require less maintenance than open systems, reducing wiping, purging, and ink waste, leading to greater efficiency and lower long-term costs. High-quality TIJ inks with extended decap times further reduce downtime.

- Environmental Control: TIJ solvent inks in sealed cartridges reduce VOC emissions, supporting a greener printing process and meeting stricter environmental regulations. As regulations on VOCs become stricter, it is essential to select solvent-based inks that comply with current environmental guidelines. This may involve using non-CMR (Carcinogenic, Mutagenic, or Reproductive toxicants) and PFAS-free formulations to address health and safety concerns.

TIJ’s advantages of fast drying, strong adhesion, and cleaner operation make it an excellent choice, while advancements in ink formulations help mitigate environmental and regulatory challenges.

UV LED Curable Inks Offer Flex Appeal

Curable inks are a preferred choice for flexible packaging.

UV-curable and LED-curable inks for piezo printing technology are engineered to deliver exceptional adhesion to non-porous flexible packaging substrates, making them ideal for high-speed production.

UV and LED inks with high-quality photoinitiators ensure fast curing while boosting durability against scratching and fading. Rapid curing also mitigates ink migration.

Benefits of UV and LED Inks

- Fast Curing: Inks with high-quality photo initiators cure instantly under UV light, allowing for immediate handling and reducing ink migration risks.

- Durability: They resist abrasion, chemicals, and environmental factors, keeping prints vibrant and intact throughout their lifecycle.

- Adhesion: Both inks adhere well to various plastic substrates, providing strong bonding that prevents peeling or flaking.

- High-Resolution Printing: Ideal for detailed and high-quality prints that require vibrant colors and long-lasting results.

Considerations

- Lamp Heat: Traditional UV curing lamps generate significant heat, which can affect heat-sensitive substrates and increase energy consumption. That’s not an issue with LED lamps, which cure at lower temperatures.

- Energy Consumption: UV lamps consume considerable energy, which may lead to higher operational costs than other curing methods.

- Cost: UV lamps cost more than LED systems and have a shorter lifespan.

A Place at the Table for Water-Based Inks

Water-based inks are increasingly used for labels applied to plastic flexible packaging or labels used on packaging. Water-based inks stand out for environmental benefits. Formulation advancements make some water-based ink compatible with printing on plastic films and foils. Traditional water-based inks perform well on non-porous facestock.

Benefits of Water-Based Inks for Labels on Plastic Flexible Packaging

- Environmental Friendliness: Water-based inks are generally more eco-friendly compared to solvent-based inks, as they emit fewer, if any, VOCs.

- High Print Quality: These inks can produce vibrant colors and sharp images, making them suitable for direct printing on flexible film or labels.

- Compliance: Water-based inks are often selected for food and beverage packaging because they comply with stringent environmental and safety standards.

Water-Based Ink Options

- Standard Inks: Traditional water-based inkjet inks are well-suited for printing on compatible facestock, offering vibrant colors and excellent print quality while maintaining environmental compliance and safety standards.

- Nanodispersion Inks: These inks use nanotechnology to create extremely fine pigment particles that adhere better to plastic surfaces. An example is the LUNAJET ink, designed for non-porous materials like thin films.

- Hybrid Inks: Water-based components combine with other adhesion-promoting agents that ensure strong adhesion to plastic substrates.

- Retort-Proof Inks: Some water-based inks are specifically designed to withstand the high temperatures and pressures of retort processing, making them suitable for flexible packaging requiring sterilization.

Advanced water-based inkjet formulations can now be effectively used for flexible food packaging production.

Food Packaging Production May Include All Three Formulations

Flexible packaging in the food industry requires versatile inkjet solutions, often relying on three primary formulations.

Solvent-based, curable, and water-based inks have unique advantages in flexible packaging.

Solvent inkjet inks are ideal for high-speed marking and coding.

UV-curable inks provide superior durability with rapid curing, making them perfect for high-resolution process color prints that need to resist abrasion and fading.

Water-based inks are increasingly favored for eco-friendly properties.

They are particularly suited for applications where sustainability is prioritized, offering good adhesion and print quality on various substrates.

They may be used for certain labels and for coding and marking secondary or tertiary cardboard packaging.

A Well-Balanced Approach

As the industry navigates the complexities of material compatibility, regulatory compliance, sustainability, and functionality, it is uniquely positioned to innovate and meet the evolving needs of on-the-go food packaging.

Balancing the cost of high-quality inks with efficient production processes requires the industry to find cost-effective ways to produce high-performance inks.

“We’re focused on providing high-performance inks that align with sustainability trends and regulatory standards, ensuring our solutions are both effective and responsible.” Ms. Wyatt said.

These challenges demand ongoing research and development, close collaboration with packaging manufacturers, and a relentless focus on innovation to meet market demands.

Contact Kao Collins to discuss the ink options for on-the-go food packaging.

Frequently Asked Questions

Inkjet printing offers high-resolution images, flexibility in design, quick turnaround times, and the ability to print on various substrates.

Common materials include polyethylene (PE), polypropylene (PP), polyester (PET), and aluminum foil. These materials offer various properties like strength, barrier protection, and flexibility.

Inkjet printing allows for high-quality graphics, precise labeling, and the ability to print variable information like expiration dates or batch codes directly onto flexible packaging.

Challenges include ensuring proper ink adhesion, avoiding smudging, and managing ink drying times on materials that may vary in texture and composition.

Future trends include advances in ink formulations for better environmental performance, improved printing technologies for higher resolution and faster speeds, and enhanced materials for more sustainable packaging solutions.

Ink properties such as viscosity, drying time, and adhesion impact print sharpness, color vibrancy, and durability on flexible materials.

Advancements include improved ink formulations, faster drying times, and enhanced print quality to meet the evolving needs of the food packaging industry, including sustainability, regulatory compliance, personalization, high-quality graphics, increased speed, efficiency, traceability and cost.