When you own a direct-to-film printer (DTF), you need to give the machine regular care and attention to extend the printer’s life and produce consistent, high-quality textile printing.

When a printer is not working correctly, it leads to workflow disruption, printer damage, work delays, and lost revenue.

Routine maintenance saves ink, avoids wasting fabric and transfer film, and saves valuable time. Keeping up with maintenance minimizes the frequency of head-cleanings and nozzle checks, or worse, replacing printheads and other components prematurely.

Ensuring that your heat-transfer printing equipment is clean is an important part of the daily routine. Doing so protects your business’s investments and saves expenses on repairs and damages.

DTF Garment Printing

Direct to film printing or DTF printing involves printing designs onto films for transfer onto garments. DTF printing is a heat transfer process of printing designs onto films, and then the adhesive powder is applied to it. The adhesive cures through heat that melts into the ink, bonding to the garment.

Inkjet Textile Inks

Learn More

Common problems with DTF printers involve failed nozzles from clogs or air bubbles.

The printers apply inkjet inks to transfer papers that are then pressed on to many types of fabric. Each substrate may require a different pre- and post-treatment.

Below are troubleshooting steps.

Common Symptoms or Problems

The best form of maintenance is a continuous operation. You will need to agitate the ink and run an automatic printhead clean before printing if operating intermittently every 2 or 3 days. DTF white ink is especially susceptible to separating and needs daily agitation. Always consult your manual and printer technician before you begin troubleshooting.

Nozzle Blockage

| Problem | Printhead won’t jet ink. |

| Cause | Ink dried in the nozzles or possible air bubbles (see below) |

| Solution | Purge the system. Run the automated cleaning process for the printer. Use high-quality ink. Maintain proper humidity and temperature |

Nozzle blockage of the DTF printhead is a common problem, and manufacturers incorporate automatic printhead cleaning systems to help reduce downtime. If the printer is not used for some time, it will also execute the automatic nozzle cleaning command when powered on. Some printers offer programmed cleaning. Consider scheduling two automatic cleanings overnight. The automated process consumes minimal amounts of ink.

Use High-Quality Inks

Ink quality directly affects the service life of the printhead of your DTF printer. Low-quality inks jeopardize equipment performance because these inks suffer from poor filtration and incorporate lower-quality components for maintaining viscosity and other ink characteristics. Low-quality inks routinely cause nozzle blockage and burnouts, requiring expensive repair costs to printheads and control mechanisms. Always choose high-quality inks from reputable brands like Kao Collins, which collaborates with printhead manufacturers.

Voltage Stability and Static Electricity of DTF Printer

Voltage stability used by DTF printers is critical. When an external voltage is too high or unstable, it impacts the printhead. This may cause the printer to burn the printhead or not recognize the printhead. It is essential to ensure the power-supply stability of your DTF printer using a power supply regulator.

Maintain Ideal Temperature and Humidity

| Problem | Ink drying rapidly on the printhead, nozzles, and material. |

| Cause | Low humidity |

| Solution | Refer to the manufacturer guide for humidity level. Install a non-wetting humidification system. |

Electrostatic discharge (ESD) – static electricity – often results from dry conditions and fabric moving across printing surfaces. Static electricity can damage printing system circuits and affect print quality.

Maintaining ideal temperature and humidity is very critical to eliminating static electricity.

Humidity level plays a crucial role in your machine’s health. DTF printers are susceptible to damage from dust and textile fibers.

Printer and ink manufacturers recommend ideal temperature and relative humidity levels for optimal performance. Low humidity causes the ink to dry prematurely and causes the printer to overheat, resulting in unnecessary head cleaning and ink flushing.

Maintain a clean environment and temperature of 65 to 80 degrees. The larger the machine, the more sensitive it is to humidity.

Use a hygrometer (humidity gauge) to measure whether the room humidity level is in the desired range of 40% to 80%. A humidifier and dehumidifier will help you adjust the room’s humidity level and keep it within the selected range.

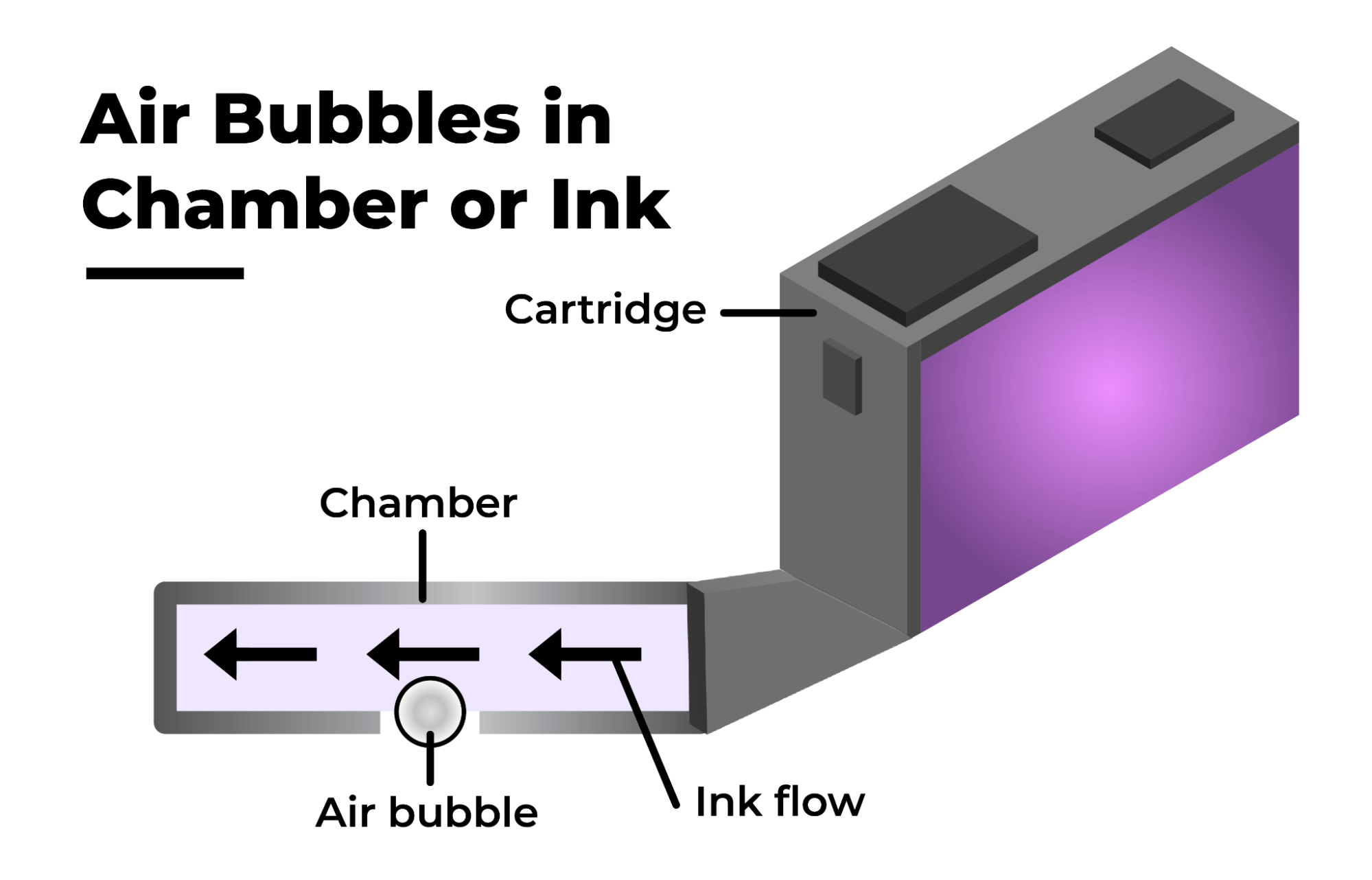

Bubbles Blocking Ink Supply

| Problem | Ink not jetting from nozzles. |

| Cause | Air bubble in ink delivery system. |

| Solution | Follow the manual for purging the nozzles. Another step is to perform an ink charge or purge to draw air rapidly through the tube. |

| Caution | Air in the tube for longer than a day may cause ink to dry. |

The next leading problem with your inkjet DTF fabric printing machine is tiny bubbles in the ink supply system that affect the nozzles and printhead. These air bubbles can quickly form a barrier at the ink inlet hole, resulting in an interruption in ink flow. This results in nozzles missing during printing.

The DTF printer must be cleaned promptly. If you continue printing without cleaning, the nozzles and printhead are prone to damage. It is best to take a few minutes of rest after printing for 1 hour and recheck ink supply systems.

Failures of Ink Cartridges

| Problem | Ink not jetting, inconsistent jetting, or missing colors |

| Cause | Ink seal on cartridge clogged or air bubbles at the cartridge outlet. |

| Solution | Open the ink seal. Perform a nozzle clean to free air in the cartridge. Check that the cartridge is firmly seated. |

Sometimes a new ink cartridge is disconnected or missing color. The possibilities are the cartridge hole seal is not cleaned, or there are air bubbles at the ink outlet of the ink cartridge. Under such circumstances, it is necessary to open the air hole seal or clean the nozzle once or twice and free the air in the damper of the nozzle.

On certain occasions, when you replace the new ink cartridge, the printer continues to indicate no ink. This could happen if the ink cartridge is not pressed into place or the sensor cartridge is not returned. Remove and reinstall the cartridge or manually reset the sensor sprint. Refer to your operating manual for details.

Monitoring of Ink Shelf Life

| Problem | Poor quality color, missing color, clogged nozzles, or supply lines. |

| Cause | Expired ink. |

| Solution | Check “use by” dates of cartridges and discard expired stock. |

Inks have expiration dates. However, people often find it hard to track the exact dates during busy work schedules consistently.

Expired ink degrades, separates, or irrevocably settles. It may clog or damage nozzles. Checking dates on delivery and setting automated notifications help you monitor the ink shelf life.

Give White Ink Special Attention

White ink settles more quickly than other inks. If you don’t intend on using white ink for a long time, use cleaning fluid or distilled water in its place, referring to manufacturer instructions. When you’re ready to start using white again, empty the cleaning solution or water and fill the bottles or cartridges with white ink. Also, at the end of each day, mildly agitate all of the cartridges of white ink.

The Daily 5-Minute DTF Cleaning Routine

- Wipe the outside of the machine with a lint-free cloth and gentle cleaner or isopropyl alcohol.

- Use manufacturer-recommended swabs or lint-free cloths to clean the inside gently. Do not use cotton swabs.

- Check the gasket on the capping station and clean it if necessary. Ink build-up can lead to clogging.

- While not touching the printhead, wipe excess ink from both sides of the printhead.

- Keep the wiper of the capping assembly clean and check that it is flexible.

- Do not use paper towels to wipe the printhead. Many tiny fiber hairs on the surface of paper easily enter the nozzle. This can cause clogging and ink dripping, affecting the print results. Wipe the surface of the nozzle with manufacturer-recommended materials only.

Contact Kao Collins for further information on inks for your DTF printers and quick troubleshooting solutions for common printing problems.