Thermal inkjet printing requires a low learning curve and not a high operator skill compared to other inkjet and analog systems. One reason is that TIJ printers use disposable print cartridges that contain both the ink supply and the printhead.

Like any combination of mechanical and technical systems, thermal printing is not without the need for routine maintenance and the occasional troubleshooting. Printing new or different products may require adjustments to optimize results or identify a printing roadblock.

Most problems are easily solved. Here’s a look at the common issues that may crop up with TIJ coding and marking, including possible solutions.

Common Equipment Problems and Troubleshooting

Whenever possible, you should refer to maintenance and troubleshooting guidance from your printer manufacturer. Some of the common printing problems that occur when using industrial TIJ printers are caused by the print cartridge’s failure to print effectively:

- Printhead getting clogged with ink, solvents, or particulates

- Print speed issues

- Product sensor issues

- Print quality is lower than normal

While prevention is better than treatment, common solutions and best practices will help industrial printers avoid coding and marking issues affecting the production of thermal inkjet or printing quality.

- Poor print quality – Dried ink in printhead nozzles is a common cause of lower-quality printing results. This will often happen when the printer is idle for a long time. Prevent it by ensuring you regularly wipe and purge the cartridge, according to manufacturer recommendations.

- Cartridge and ink failure – Storing printer cartridges in the manufacturer’s recommended conditions minimizes the chances of failure and prolongs shelf life. Discard expired ink, otherwise, you risk letting the ink degrade the cartridge or printhead. Many inks have a shelf life of a year or less. The patented SIGMA solvent ink for HP systems from Kao Collins is an exception, with a two-year shelf life.

- Excessive downtime – Ink may dry on TIJ printheads during product changes or other production delays. Wipe cartridges carefully and purge them to get the ink flowing again when this happens. The ink manufacturer specifies the average decap time. It is often brief. SIGMA solvent ink can remain idle for 12 hours, about four times longer than other solvent inks.

Printer not printing – While possible, TIJ printhead cartridges have high reliability. Check that sensors are triggering the printer at the right time. The sensor may be improperly aligned. This causes the printer to fire before or after the product passes the printer. If everything is aligned, try changing out a cartridge to test the system further. Factory-new cartridges are less prone to failure compared to aftermarket or remanufactured cartridges. High-quality ink manufacturers like Kao Collins use factory-new cartridges.

Printer not printing – While possible, TIJ printhead cartridges have high reliability. Check that sensors are triggering the printer at the right time. The sensor may be improperly aligned. This causes the printer to fire before or after the product passes the printer. If everything is aligned, try changing out a cartridge to test the system further. Factory-new cartridges are less prone to failure compared to aftermarket or remanufactured cartridges. High-quality ink manufacturers like Kao Collins use factory-new cartridges.- Print Speed Issues: The printer’s speed can sometimes cause print misfiring and print quality issues. The conveyor and print speed settings must match to execute the print job successfully. If these two settings don’t match, it will result in distorted print images or incorrect placement. Use an encoder to accurately calculate the print speed settings on demand for each product passing by the printhead.

- High ink consumption – TIJ printers are versatile machines that can create everything from barcodes to company logos. Consider changing fonts or lowering dpi settings to reduce ink consumption if you use your TIJ printer for ink-heavy applications.

- Ink is faint or doesn’t reach the substrate – The solution for washed-out or faint reproduction may not be as simple as ink not contacting the product or substrate. If the ink appears washed out, the printhead may be too far from the target. TIJ printers have an optimal throw distance that the ink can travel from the nozzles to the substrate. TIJ cartridges from HP have 5 mm throw distances. Funai’s Zion cartridges have 10 mm throw distances.

Environmental Problems

The temperature and humidity of the environment in the industrial printing plant affect the print quality, ink, and equipment. Being mindful of these factors and maintaining them properly is essential to avoiding issues with production.

Operating in the Recommended Temperature Range

Printer and ink manufacturers recommend operating equipment within an optimal temperature range, often between 60°F and 95°F (16°C and 35°C).

- Too cold – If temperatures are too cold, the TIJ ink thickens and doesn’t reach the temperature to vaporize and jet effectively.

- Too hot – Conversely, hotter temperatures thin the ink causing unreliable over-jetting. Excessive heat can also damage the cartridge.

Controlling Relative Humidity

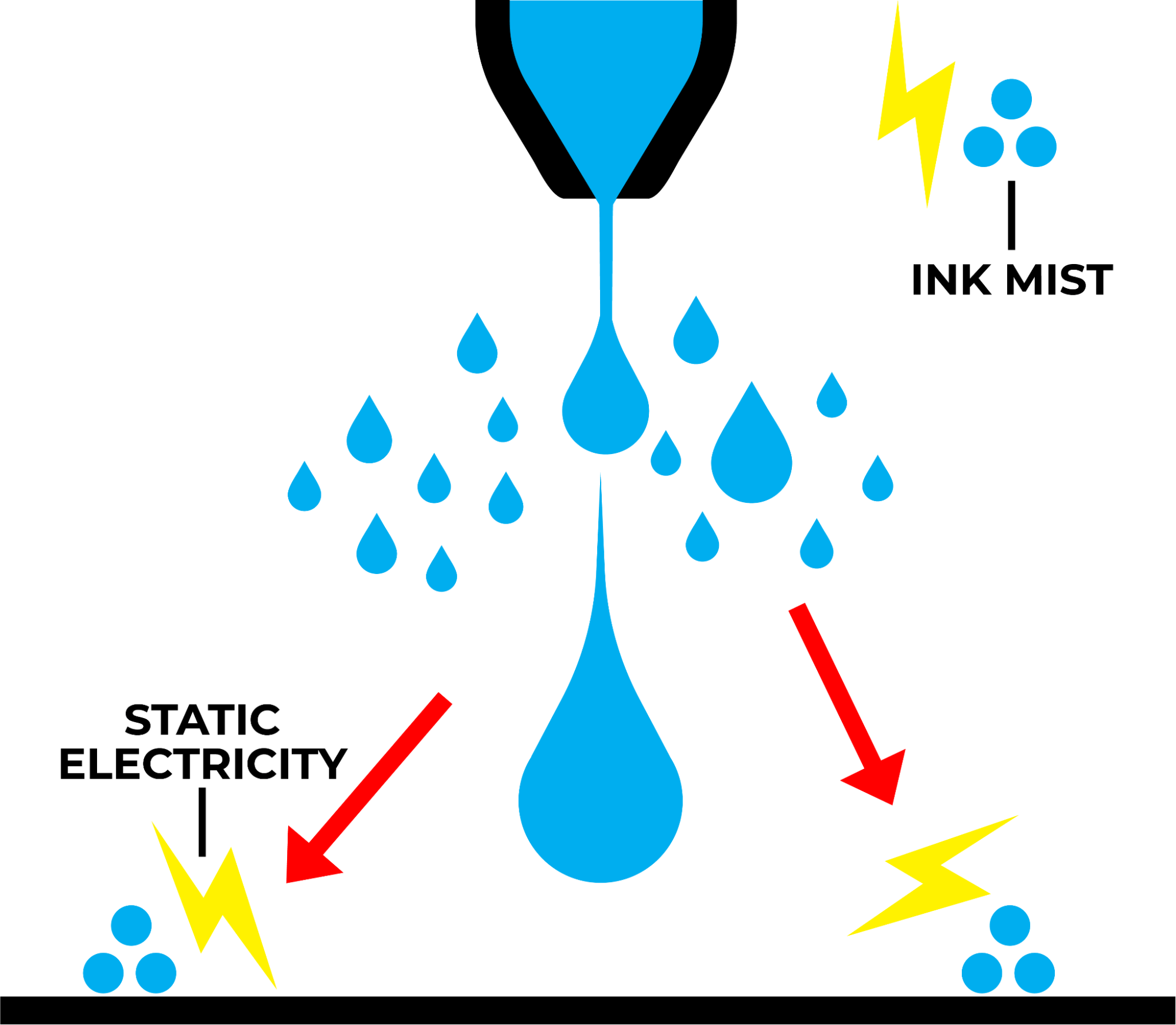

The experience of static shock – resulting from an imbalance between negative and positive charges and occurring most often in winter – happens in environments with low relative humidity.

Industrial printing systems create the ideal conditions for generating electrostatic discharge. Like shuffling your feet across the carpet, the movement of substrates past a printhead can increase the likelihood of static electricity.

Too much static electricity can lead to an array of problems that typically slow production and interfere with the printing process:

Printing Problems Caused by Static Electricity

- Printing artifacts

- Software glitches or failure

- Slower operating speeds

- Communication errors

- Memory dumps

- Poor ink placement

- Damaged printheads

Solutions for Minimizing Electrostatic Discharge

Electronic equipment reacts poorly to static electricity. Static discharge can also create dangerous conditions depending on the flammability of inks or solvents. You can take several steps to reduce the risk of static electricity in the inkjet printing environment:

- Use approved cable connectors. These cables are shielded to prevent interference, including arcing from static electricity.

- Ground all electrical equipment

- Maintain a 40-60% relative humidity with a non-wetting humidification system. Refer to manufacturer recommendations for your printer and inks.

- Wipe the media surface with alcohol or spray antistatic spray to reduce the static electricity.

Contact Kao Collins about ink storage, throw distance, and the effects of environmental conditions on print quality.

Frequently Asked Questions

Dust or particles may be causing obstructions on the printhead or the substrate.

The following ways can resolve this.

- Check throw distance first and adjust

- Inspect and clean the printhead

- Replace the cartridge if necessary

No, you should not shake a TIJ cartridge.

- It may inject air into the cartridge and create bubbles.

- Cover cartridges when not in use.

Yes. Too much humidity and too little humidity can cause problems.

When the printer is humid, the moisture content can distort the substrate, making it warped, wavy, or curled. This can disrupt the function of the printer due to jams. It can also cause streaks and smudging during printing, diminishing print quality.

Thermal inkjet printing is used for publishing, direct mail printing, wide-format signage, and marking and coding on metal, glass, and plastics.